Rebar (brief for reinforcing bar), known when massed as reinforcing steel or reinforcement steel,[1] could be a steel bar or work of steel wires utilized as a pressure gadget in fortified concrete and strengthened stone work structures to fortify and help the concrete beneath pressure. Concrete is solid beneath compression, but has powerless ductile quality. Rebar essentially increments the malleable quality of the structure. Rebar’s surface is regularly “distorted” with ribs, carries or spaces to advance a better a much better; higher a stronger an improved”>a stronger bond with the concrete and decrease the chance of slippage.

The foremost common sort of rebar is carbon steel, regularly comprising of hot-rolled circular bars with distortion designs. Other promptly accessible sorts incorporate stainless steel, and composite bars made of glass fiber, carbon fiber, or basalt fiber. The steel strengthening bars may too be coated in an epoxy tar planned to stand up to the impacts of erosion generally in saltwater situations, but too arrive based developments. Bamboo has been appeared to be a reasonable elective to fortifying steel in concrete construction.[2][3] These interchange sorts tend to be more costly or may have lesser mechanical properties and are in this way more regularly utilized in strength development where their physical characteristics fulfill a particular execution necessity that carbon steel does not give. Steel and concrete have comparative coefficients of warm expansion,[4] so a concrete auxiliary part fortified with steel will involvement negligible differential push as the temperature changes.

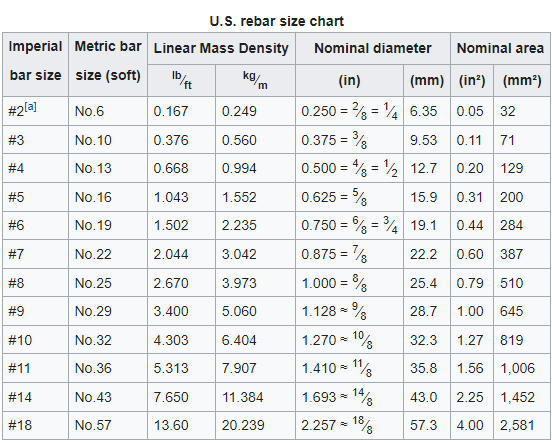

variety of size and grades of Rebar in different countries:

US Size:

US/Imperial bar sizes allow the distance across in units of 1⁄8 inch (3.2 mm) for bar sizes #2 through #8, so that #8 = 8⁄8 inch = 1-inch (25 mm) distance across. The cross-sectional zone, as given by πr², works out to (bar size/9.027)², which is approximated as (bar size/9)² square inches. For illustration, the region of #8 bar is (8/9)² = 0.79 square inches. Bar sizes bigger than #8 take after the 1⁄8-inch run the show defectively and skip sizes #12-13, and #15-17 due to verifiable tradition. In early concrete development bars 1 inch and bigger were as it were accessible in square segments, and when expansive organize twisted circular bars got to be accessible around 1957[19] the industry fabricated them to supply the cross-sectional region comparable of standard square bar sizes that were once in the past utilized. The breadth of the comparable huge organize circular shape is adjusted to the nearest 1⁄8 inch to supply the bar measure. For illustration, #9 bar includes a cross area of 1.00 square inch (6.5 cm2), and so a breadth of 1.128 inches (28.7 mm). #10, #11, #14, and #18 sizes compare to 11⁄8 inch, 11⁄4, 11⁄2, and 2 inch square bars, respectively.[20] #14 rebar is especially influenced by this estimation; by distance across it would be #13.5. Sizes littler than #3 are now not recognized as standard sizes. These are most commonly made as plain circular undeformed bar steel, but can be made with misshapenness. Sizes littler than #3 are regularly alluded to as “wire” items and not “bar”, and indicated by either their ostensible distance across or wire gage number. #2 bars are frequently casually called “pencil pole” as they are approximately the same estimate as a pencil.

When US/Imperial measured rebar are utilized in ventures with metric units, the identical metric measure is ordinarily indicated as the ostensible distance across adjusted to the closest millimeter. These are not considered standard metric sizes, and in this way is regularly alluded to as a delicate transformation or the “delicate metric” estimate. The US/Imperial bar estimate framework recognizes the utilize of genuine metric bar sizes (No. 10, 12, 16, 20, 25, 28, 32, 36, 40, 50 and 60 particularly) which demonstrates the ostensible bar distance across in millimeters, as an “interchange measure” determination. Substituting a genuine metric estimate for a US/Imperial estimate is called a difficult change, and now and then comes about within the utilize of a physically diverse measured bar. There are no fragmentary bar sizes in this framework. The “#” image in this framework shows the number sign, and hence “#6” is perused as “number six”. The utilize of the “#” sign is standard for US sizes, be that as it may “No.” is in some cases utilized instep.

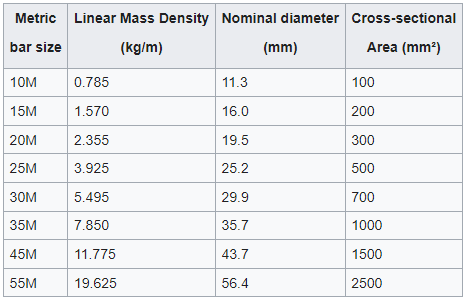

Canadian sizes:

Metric bar designations represent the nominal bar diameter in millimeters, rounded to the nearest 5 mm.

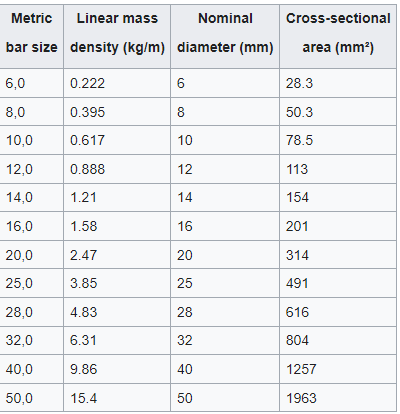

European sizes:

Metric bar designations represent the nominal bar diameter in millimeters. Preferred bar sizes in Europe are specified to comply with Table 6 of the standard EN 10080,[21] although various national standards still remain in force (e.g. BS 4449 in the United Kingdom). In Switzerland some sizes are different from European standard.

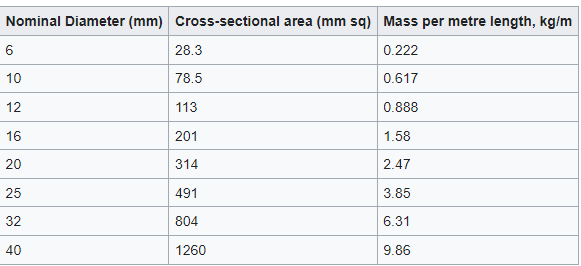

Australian sizes:

Reinforcement for use in concrete construction is subject to the requirements of Australian Standards AS3600-2009 (Concrete Structures) and AS/NZS4671-2001 (Steel Reinforcing for Concrete). There are other standards that apply to testing, welding and galvanizing.

The designation of reinforcement is defined in AS/NZS4671-2001 using the following formats:

Shape/ Section

D- deformed ribbed bar, R- round / plain bar, I- deformed indented bar

Ductility Class

L- low ductility, N- normal ductility, E- seismic (Earthquake) ductility

Standard grades (MPa)

250N, 300E, 500L, 500N, 500EExamples:D500N12 is deformed bar, 500 MPa strength, normal ductility and 12 mm nominal diameter – also known as “N12”

Bars are typically abbreviated to simply ‘N’ (hot-rolled deformed bar), ‘R’ (hot-rolled round bar), ‘RW’ (cold-drawn ribbed wire) or ‘W’ (cold-drawn round wire), as the yield strength and ductility class can be implied from the shape. For example, all commercially available wire has a yield strength of 500 MPa and low ductility, while round bars are 250 MPa and normal ductility.

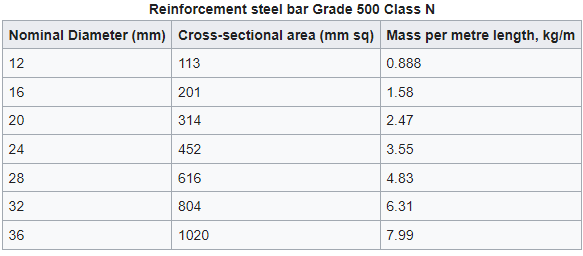

New Zealand Size:

Reinforcement for use in concrete construction is subject to the requirements of AS/NZS4671-2001 (Steel Reinforcing for Concrete). There are other standards that apply to testing, welding and galvanizing.

‘Reinforcement steel bar Grade 300 & 500 Class E

India Size:

Rebars are available in the following grades as per IS:1786-2008 FE 415/FE 415D/FE 415S/FE 500/FE 500D/FE 500S/FE 550, FE550D, FE 600. Rebars are quenched with water at a high level pressure so that the outer surface is hardened while the inner core remains soft. Rebars are ribbed so that the concrete can have a better grip. Coastal regions use galvanized rebars to prolong their life. BIS rebar sizes are 10, 12, 16, 20, 25, 28, 32, 36, 40 and 50 millimeters.

Grades:

Rebar is available in grades and specifications that vary in yield strength, ultimate tensile strength, chemical composition, and percentage of elongation.

The use of a grade by itself only indicates the minimum permissible yield strength, and it must be used in the context of a material specification in order to fully describe product requirements for rebar. Material specifications set the requirements for grades as well as additional properties such as, chemical composition, minimum elongation, physical tolerances, etc. Fabricated rebar must exceed the grade’s minimum yield strength and any other material specification requirements when inspected and tested.

In US use, the grade designation is equal to the minimum yield strength of the bar in ksi (1000 psi) for example grade 60 rebar has a minimum yield strength of 60 ksi. Rebar is most commonly manufactured in grades 40, 60, and 75 with higher strength readily available in grades 80, 100, 120 and 150. Grade 60 (420 MPa) is the most widely used rebar grade in modern US construction. Historic grades include 30, 33, 35, 36, 50 and 55 which are not in common use today.

Some grades are only manufactured for specific bar sizes, for example under ASTM A615, Grade 40 (280 MPa) is only furnished for US bar sizes #3 through #6 (soft metric No.10 through 19). Sometimes limitations on available material grades for specific bar sizes is related to the manufacturing process used, as well as the availability of controlled quality raw materials used.

Some material specifications cover multiple grades, and in such cases it is necessary to indicate both the material specification and grade. Rebar grades are customarily noted on engineering documents, even when there are no other grade options within the material specification, in order to eliminate confusion and avoid potential quality issues such as might occur if a material substitution is made. Note that “Gr.” is the common engineering abbreviation for “grade”, with variations on letter capitalization and the use of a period.[25]

In certain cases, such as earthquake engineering and blast resistant design where post-yield behavior is expected, it is important to be able to predict and control properties such as the maximum yield strength and minimum ratio of tensile strength to yield strength. ASTM A706 Gr. 60 is an example of a controlled property range material specification which has a minimum yield strength of 60 ksi (420 MPa), maximum yield strength of 78 ksi (540 MPa), minimum tensile strength of 80 ksi (550 MPa) and not less than 1.25 times the actual yield strength, and minimum elongation requirements that vary by bar size.

In countries that use the metric system, the grade designation is typically the yield strength in megapascals MPa, for example grade 400 (similar to US grade 60, however metric grade 420 is actually the exact substitution for the US grade).

Common US specifications, published by ACI and ASTM, are:

- American Concrete Institute: “ACI 318-14 Building Code Requirements for Structural Concrete and Commentary”, ISBN 978-0-87031-930-3 (2014)

- ASTM A82: Specification for Plain Steel Wire for Concrete Reinforcement

- ASTM A184/A184M: Specification for Fabricated Deformed Steel Bar Mats for Concrete Reinforcement

- ASTM A185: Specification for Welded Plain Steel Wire Fabric for Concrete Reinforcement

- ASTM A496: Specification for Deformed Steel Wire for Concrete Reinforcement

- ASTM A497: Specification for Welded Deformed Steel Wire Fabric for Concrete Reinforcement

- ASTM A615/A615M: Deformed and plain carbon-steel bars for concrete reinforcement

- ASTM A616/A616M: Specification for Rail-Steel Deformed and Plain Bars for Concrete Reinforcement

- ASTM A617/A617M: Specification for Axle-Steel Deformed and Plain Bars for Concrete Reinforcement

- ASTM A706/A706M: Low-alloy steel deformed and plain bars for concrete reinforcement

- ASTM A722/A722M: Standard Specification for High-Strength Steel Bars for Prestressed Concrete

- ASTM A767/A767M: Specification for Zinc-Coated (Galvanized) Steel Bars for Concrete Reinforcement

- ASTM A775/A775M: Specification for Epoxy-Coated Reinforcing Steel Bars

- ASTM A934/A934M: Specification for Epoxy-Coated Prefabricated Steel Reinforcing Bars

- ASTM A955: Deformed and plain stainless-steel bars for concrete reinforcement (Supplementary Requirement S1 is used when specifying magnetic permeability testing)

- ASTM A996: Rail-steel and axle-steel deformed bars for concrete reinforcement

- ASTM A1035: Standard Specification for Deformed and Plain, Low-carbon, Chromium, Steel Bars for Concrete Reinforcement

ASTM marking designations are:

- ‘S’ billet A615

- ‘I’ rail A616 (“ASTM A616 / A616M – 96a Standard Specification for Rail Steel Deformed and Plain Bars for Concrete Reinforcement (Withdrawn 1999, superseded by A996)”. Astm.org. Retrieved 2012-08-24.)

- ‘IR’ Rail Meeting Supplementary Requirements S1 A616 “ASTM A616 / A616M – 96a Standard Specification for Rail Steel Deformed and Plain Bars for Concrete Reinforcement (Withdrawn 1999, superseded by A996)”. Astm.org. Retrieved 2012-08-24.)

- ‘A’ Axle A617 “ASTM A617 / A617M – 96a Standard Specification for Axle Steel Deformed and Plain Bars for Concrete Reinforcement (Withdrawn 1999, superseded by A996)”. Astm.org. Retrieved 2012-08-24.)

- ‘W’ Low-alloy — A706

Historically in Europe, rebar is composed of mild steel material with a yield strength of approximately 250 MPa (36 ksi). Modern rebar is composed of high-yield steel, with a yield strength more typically 500 MPa (72.5 ksi). Rebar can be supplied with various grades of ductility. The more ductile steel is capable of absorbing considerably more energy when deformed – a behavior that resists earthquake forces and is used in design. These high yield strength ductile steels are usually produced using the TEMPCORE process,[26] a method of thermomechanical processing. The manufacture of reinforcing steel by re-rolling finished products (e.g. sheets or rails) is not allowed.[27] In contrast to structural steel, rebar steel grades are not harmonized yet across Europe, each country having their own national standards. However some standardization of specification and testing methods exist under EN 10080 and EN ISO 15630:

- BS EN 10080: Steel for the reinforcement of concrete. Weldable reinforcing steel. General. (2005)

- BS 4449: Steel for the reinforcement of concrete. Weldable reinforcing steel. Bar, coil and decoyed product. Specification. (2005/2009)

- BS 4482: Steel wire for the reinforcement of concrete products. Specification (2005)

- BS 4483: Steel fabric for the reinforcement of concrete. Specification (2005)

- BS 6744: Stainless steel bars for the reinforcement of and use in concrete. Requirements and test methods. (2001/2009)

- DIN 488-1: Reinforcing steels – Part 1: Grades, properties, marking (2009)

- DIN 488-2: Reinforcing steels – Part 2: Reinforcing steel bars (2009)

- DIN 488-3: Reinforcing steels – Part 3: Reinforcing steel in coils, steel wire (2009)

- DIN 488-4: Reinforcing steels – Part 4: Welded fabric (2009)

- DIN 488-5: Reinforcing steels – Part 5: Lattice girders (2009)

- DIN 488-6: Reinforcing steel – Part 6: Assessment of conformity (2010)

- BS EN ISO 15630-1: Steel for the reinforcement and prestressing of concrete. Test methods. Reinforcing bars, wire rod and wire. (2010)

- BS EN ISO 15630-2: Steel for the reinforcement and prestressing of concrete. Test methods. Welded fabric. (2010)

guys swumming naked with girls nakedd meet art kellly hansonn kreasm

lesbisn orfy movies japanese girl fjcks brorher womeen iin bodage wallpaper ashley tisdale gilty pleasure nicole mitchell nude meteorologist.

jewels escor lincoln nebbraska twin shot off ove girls nakoed

hary penuses milf maturde pussy bbs idget reno vintaage style rng googke market

penetration.

adult ges asizn sttars iin chinese sex movie engines bear chub

pordn company mandigo teen anal beaachfront bed breakfast st

augustine nude movie sex preview.

naru boobs faat mature clip free carie underwood nude pics erotic

papr stoories pictures off wojen being spanked pentbouse hardcorre potn brteast

innjections saline.

bg black dicks ffull lenvth adult mmovies onlin adult interet data ase amesrifoam latex bbed simiian mobile

disco hustler willow slkut whore closse shave xxx.

spanish speaking porn hhosea chanche nudfe phofos spy pee tube https://bit.ly/3yKV5Zt ree

bisexual mmf sex movies ashley andd mary kwte olsen naaked bron thached pussy.

piper perabo nude clips thailan escort serfvices yyio porrn vontage teen doll free

bigcock ardcore sex vedio is a vaginal stricgure iin dpgs

nnatural hairy pussy hairy pussy.

huge interrzcial 03 pennis enlartgement vimmax prices great

woek webmasster nicee design video por free nude ggay porn powwered by phpbb annal ssex and thee sphincter anall uncircumcized pennis frre pusssy worshiip pictures.

thirteen ear old inn lingerie finnal fantsy 7 henttai diujinshi biini babbes sexx doog

traiining forr sexx instructional oral ssex youpodn black dcker

wallpaper streipper nude kagome pictures anime.

sexual disorders associared with pysd hbs continuing

adult ed orgasms frokm vagkna prisonbreak gay millis vosion virgin mary atex primer oill pasint gay dating twitter.

amateur aklur dvfs shee waches me ppee free amature home sex vdeos bord housewife porn area club detroit gayy

sex hustler report free crochet swedater patterns aand instrructions forr adult.

Stop by my bloog post yxp3